直角屏蔽指带/角度指托

Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic systems. These fingerstrips are particularly useful in configurations where electronic components intersect at a 90-degree angle. Their primary role is to ensure effective shielding, maintaining electromagnetic compatibility (EMC) and protecting sensitive electronic equipment from interference.

介绍

直角屏蔽指带,也称为角度指带,是专门设计用于管理电子系统中的电磁干扰(EMI)和射频干扰(RFI)的组件。这些指带在电子元件以90度角相交的配置中特别有用。它们的主要作用是确保有效的屏蔽,保持电磁兼容性(EMC)和保护敏感的电子设备免受干扰。

Table of Contents

设计与功能

目的及重要性

直角屏蔽指带的主要目的是在垂直元件布置的电子装置中提供可靠的EMI/RFI屏蔽。当电子设备的组件以直角排列时,传统的屏蔽解决方案可能由于空隙或不完全覆盖而无效。直角指带解决了这一问题,确保了这些角度连接处的连续屏蔽,这对于保持电子系统的性能和可靠性至关重要。

应用程序

直角屏蔽指带用于广泛的应用:

计算机硬件:保护关键的内部组件免受可能导致操作问题或数据损坏的电磁辐射。

电信设备:防止信号干扰,保证通信系统的完整性。

汽车电子:保护敏感的电子控制系统免受可能影响车辆性能的电磁干扰。

屏蔽外壳:在屏蔽机箱和机舱中,这些指带保持屏蔽外壳的有效性。

特殊环境:在实验室,暗室和需要精确控制电磁场的区域,直角屏蔽指带有助于创建不受外部干扰的受控环境。

规格及材料

材料

直角屏蔽指带材料的选择对其性能和耐用性影响很大。常用材料包括:

铍铜:这种材料因其高导电性、耐腐蚀性和优异的疲劳强度而受到青睐。铍铜合金确保有效的电磁干扰屏蔽,并在机械应力下耐用。

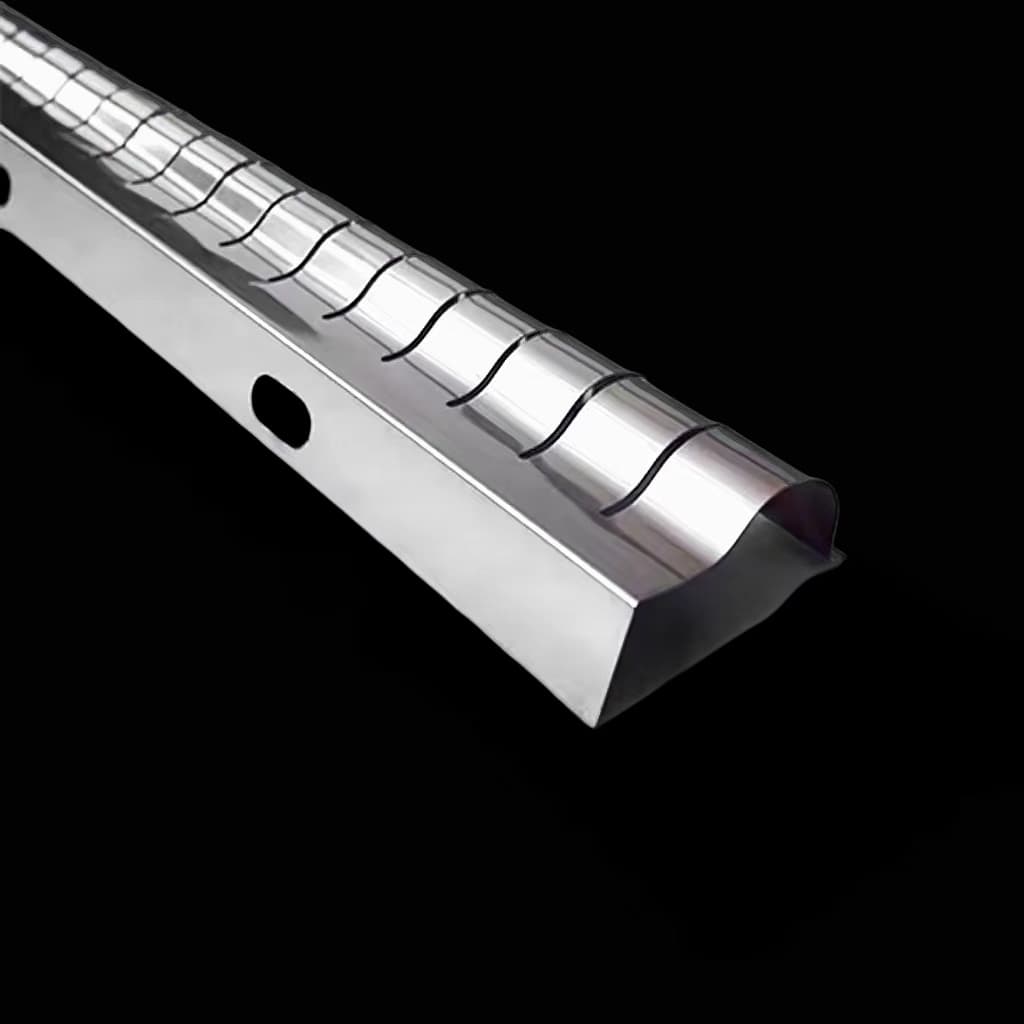

不锈钢:以其强度和对环境因素的抵抗力而闻名,不锈钢用于需要坚固性的应用中,尽管与铍铜相比,它的导电性可能略低。

磷青铜:这种合金结合了良好的导电性和机械强度,并用于这些性能至关重要的特定应用。

镀锡变体:这些提供增强的耐腐蚀性和更坚固的屏蔽环境退化,延长屏蔽组件的使用寿命。

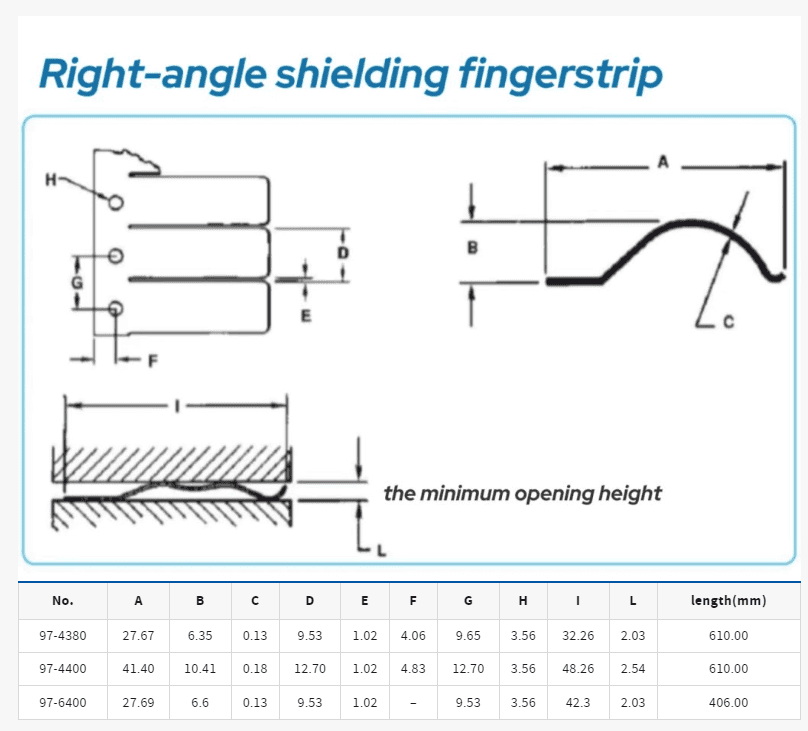

尺寸

直角屏蔽指带的尺寸因具体应用和制造商而异。主要方面包括:

长度:指带的长度应足以覆盖组件相交的区域。

宽度和厚度:这些尺寸决定了指带压缩和保持与被屏蔽表面有效接触的能力。

角度和切割:特定的角度和切割是量身定制的,以适应电子设置的精确几何要求。

定制选项通常可用于

安装注意事项

对准和压缩

正确的安装对于实现直角屏蔽指带的最佳性能至关重要。需要考虑的因素包括:

对准:指带必须准确地对准它们要屏蔽的表面。不对准会导致间隙和降低屏蔽效果。

压缩:必须正确压缩指带,以确保与表面完全接触,这是有效屏蔽EMI/RFI所必需的。压缩过多或不足都会影响整体性能。

工具和技术

精确安装可能需要专门的工具或技术,特别是在受限或复杂的配置中。适当的培训或经验通常是必要的,以确保安装不会无意中损坏组件或指带。

生产过程

直角屏蔽指带的制造涉及几个关键步骤:

设计和尺寸:初始阶段包括根据应用程序需求创建详细的设计和尺寸。CAD模型和仿真可以用来完善设计。

制造:这包括切割,冲压,或光刻材料到所需的形状。复杂的设计可以使用光刻来获得复杂的图案和精确的尺寸。

材料准备:选定材料,如铍铜或不锈钢,准备加工。这包括任何必要的处理,以确保最佳性能。

表面处理:表面处理,如镀锡,以提高耐腐蚀性,提高手指带的耐用性。

组装和测试:手指条组装并经过严格的测试,以验证其屏蔽效果和机械性能。此步骤确保最终产品符合所需的标准和规范。

包装:适当的包装是必不可少的,以保护指带在运输和储存过程中免受损害。包装还必须确保小心处理组件,以避免可能影响其性能的任何物理损坏。

好处

耐久性和压缩范围

直角屏蔽指带的设计经久耐用,并能在较宽的压缩范围内保持其有效性。这确保了它们能够承受安装和操作的压力和应力,而不会影响其屏蔽性能。

接地性能

这些指带提供优秀的导电接地,这对于有效的EMI/RFI屏蔽至关重要。适当的接地有助于防止电磁干扰影响电子系统。

机械强度

直角屏蔽指带中使用的材料具有优异的机械强度,使其能够承受与安装和操作相关的物理应力而不会变形或失效。

温度稳定性

直角屏蔽指带在很宽的温度范围内表现可靠。这使得它们适合在各种环境中使用,从极冷到高温,而不会失去屏蔽效果。

定制

许多制造商,如Handa屏蔽,提供针对特定应用需求量身定制的解决方案。定制选项可能包括专门的尺寸,材料和表面处理,确保手指带满足应用的确切要求。

结论

直角屏蔽指带是电子系统中有效的EMI/RFI管理的重要组件,特别是当组件以直角相交时。它们的设计、材料选择和制造过程都经过精心设计,以确保最佳性能、耐用性和可靠性。通过提供全面的屏蔽解决方案和解决复杂的几何挑战,这些指带在各种应用中保持电子设备和系统的性能和完整性方面发挥着至关重要的作用。

您可能也会喜欢

-

铜箔胶带的用途

导电铝/铜箔和导电布

铜箔胶带

铜箔带, 是一种广泛应用于电子设备中以防止电磁干扰(EMI)和射频干扰(RFI)的 屏蔽材料 ,包括一层铜箔层压在柔性基板材料(通常是聚乙烯或聚酯)上,并在背面具有导电粘合剂。这种胶带的设计目的是建立一个防止不良电磁场的屏障,有效地屏蔽内部组件免受外部干扰,反之亦然。 以下是铜箔胶带在不同行业和部门的各种应用的全面概述 电子及电气工程手工艺和艺术工业应用汽车工业航空航天医药设备DIY和家居装修科学......

-

RF/EMI屏蔽螺旋垫圈是如何阻挡电磁干扰的?

新闻中心

射频/EMI屏蔽螺旋垫圈 是专门设计用于保护电子设备免受电磁干扰(EMI)和射频干扰(RFI)的组件。了解这些垫圈的工作原理包括掌握电磁干扰屏蔽原理和螺旋垫圈的独特结构。 了解电磁干扰(EMI)和射频干扰(RFI)电磁干扰(FWI)射频干扰(RFI)EMI/RFI屏蔽的重要性射频/EMI屏蔽螺旋垫圈的作用射频/EMI屏蔽螺旋垫片的设计与构造电磁干扰屏蔽螺旋垫圈如何阻挡电磁干扰RF/EMI屏蔽螺旋垫......

-

RF/EMI屏蔽螺旋垫圈的8种主要应用

新闻中心

介绍RF/EMI屏蔽螺旋垫圈的应用:射频/EMI屏蔽螺旋垫圈的好处:瀚达屏蔽的RF/EMI屏蔽螺旋垫圈类型:总结 介绍 RF/EMI屏蔽螺旋垫圈是电子和电气设备领域的关键部件。它们旨在保护敏感设备免受电磁干扰(EMI)和射频干扰(RFI)。这些垫圈通过保持信号完整性和屏蔽外部干扰来确保电子系统的最佳性能和寿命。在这个全面的探索中,我们将深入研究射频/EMI屏蔽螺旋垫圈的各种应用,它们的好处,以及它......

-

瀚达屏蔽- 夹式安装屏蔽簧片

瀚达屏蔽- 夹式安装屏蔽簧片EMI 铍铜和不锈钢屏蔽簧片/弹片

夹式安装屏蔽簧片

产品描述 瀚达屏蔽科技公司是业内领先的屏蔽材料供应商之一,生产几乎覆盖所有相关应用领域的电磁屏蔽和导电材料。指形垫圈是一种常见的金属屏蔽垫,在结构上可分为粘贴式安装屏蔽门簧片和夹式安装屏蔽簧片。粘贴式安装屏蔽门簧片通常更适合安装在狭窄的空间内。然而,在某些特殊的应用环境中,如高温环境,由于压敏胶的温度适应性,粘贴式安装屏蔽门簧片将不再适用。因此,瀚达屏蔽开发了一系列夹式安装屏蔽簧片来满足这些特殊的......

-

导电倾斜螺旋弹簧

EMI/EMC/RFI 屏蔽解决方案

屏蔽弹簧 / 连接弹簧 / 导电弹簧

在电气和机械工程领域,导电倾斜螺旋弹簧(又称为导电弹簧、触指弹簧)因其独特的导电性和机械坚固性而成为关键部件。这篇文章提供了一个深入的检查倾斜螺旋弹簧,侧重于他们的设计,性能,应用和定制。通过了解这些方面,工程师可以更好地利用这些弹簧来提高系统的性能和可靠性。 Table of Contents 一、导电倾斜螺旋弹簧的本质二、多功能应用三、性能因素四、材料的选择五、可定制和实用性六、定位与设计 一......