导电倾斜螺旋弹簧

Electrical Conducting Springs, such as the Handa Shielding Spring® canted coil spring are springs specifically designed to conduct electrical current while providing mechanical support. Made from highly conductive materials such as copper alloys or stainless steel, these springs facilitate the flow of electricity through electronic and electrical systems.

在电气和机械工程领域,导电倾斜螺旋弹簧(又称为导电弹簧、触指弹簧)因其独特的导电性和机械坚固性而成为关键部件。这篇文章提供了一个深入的检查倾斜螺旋弹簧,侧重于他们的设计,性能,应用和定制。通过了解这些方面,工程师可以更好地利用这些弹簧来提高系统的性能和可靠性。

Table of Contents

一、导电倾斜螺旋弹簧的本质

导电倾斜线圈弹簧的特点是它们的角度线圈配置,这使它们有别于传统的弹簧。这种设计特点使占地面积更小,允许在更少的空间内管理更多的功率,同时保持更低的工作温度。线圈的角度布置不仅优化了空间,而且改善了散热。这在热管理至关重要的应用中尤其有利,因为它可以最大限度地减少热量上升,并确保即使在冲击和振动下也能保持一致、可靠的电气连接。

导电斜盘式线圈弹簧的设计包括将导线缠绕成螺旋形状,然后稍微倾斜。这导致弹簧可以处理各种电流水平(高,中,低) 。该设计对热和机械应力的弹性使其成为可靠性和性能至关重要的环境的理想选择。

二、多功能应用

倾斜螺旋弹簧以其多功能性而闻名,可用于各种配置:

外壳安装配置:这些弹簧通常用于安装在外壳内的设备。这种结构有利于在密闭空间内要求稳定的电气连接和可靠的机械性能的应用。

活塞安装配置:在活塞安装应用中,导电倾斜线圈弹簧提供有效的导电和机械连接能力。它们处理动力和在运动中保持接触的能力使它们适合活塞系统。

倾斜螺旋弹簧的设计灵活性允许与各种轮廓的凹槽合并,包括圆形,扁平或“V”形底部。这种定制满足了特定的应用要求,无论是在静态或动态环境中导电还是接地。多功能性确保倾斜螺旋弹簧可以量身定制,以满足不同应用的需求。

三、性能因素

影响倾斜旋螺弹簧性能的几个关键设计因素:

1.线材

线材的选择对弹簧的性能影响很大。常见的材料包括铜合金和不锈钢,每种材料都具有独特的机械和电气性能组合。铜合金通常因其优异的导电性而被选择,而不锈钢则具有耐久性和耐腐蚀性。

2.直径和线圈高度

电线的直径和线圈的高度影响弹簧的机械性能,包括它的力和灵活性。这些尺寸的精度确保弹簧可以处理所需的负载并在应力下保持其形状。

3.弹簧力

弹簧力是一个关键参数,决定了弹簧能施加的力的大小。工程师必须仔细计算这个力,以确保弹簧满足应用的特定需求。

4.电镀厚度

对于需要增强导电性或防止腐蚀的应用,可以用银等金属电镀。镀层的厚度影响电导率和对环境因素的抵抗力。

倾斜线圈弹簧的设计,以管理连续的电流范围,抗压缩集,并补偿错位和公差变化。这种性能使它们成为需要导电和机械连接的应用的理想选择。

四、材料的选择

选择用于导电倾斜线圈弹簧的材料,是因为它们能够提供机械强度和导电性的平衡:

1.铜合金

铜合金因其优良的导电性而被广泛使用。它们适用于许多无需额外电镀的应用,尽管它们可能并不总是提供所需的耐腐蚀性水平。

2.不锈钢

不锈钢提供耐用性和耐腐蚀性,使其适合更苛刻的环境。它经常与其他材料结合使用以提高性能。

3.电镀材料

为了提高性能,特别是在潮湿或腐蚀性环境中,可以使用银等金属电镀。镀银增加导电性,并提供额外的防腐保护。保护涂层也适用于镀银接触元件,以提高其对环境因素的抵抗力。

五、可定制和实用性

倾斜螺旋弹簧可以定制,以满足各种应用的具体需求。它们具有各种尺寸的非焊接长度,可容纳简单和复杂的凹槽配置。考虑到每个应用的独特要求,导电倾斜线圈弹簧没有标准尺寸或类型。相反,制造商维护一个通常要求的直径和横截面的数据库,以便简化定制。这种方法确保工程师可以在不影响性能的情况下获得适合其特定需求的弹簧。

六、定位与设计

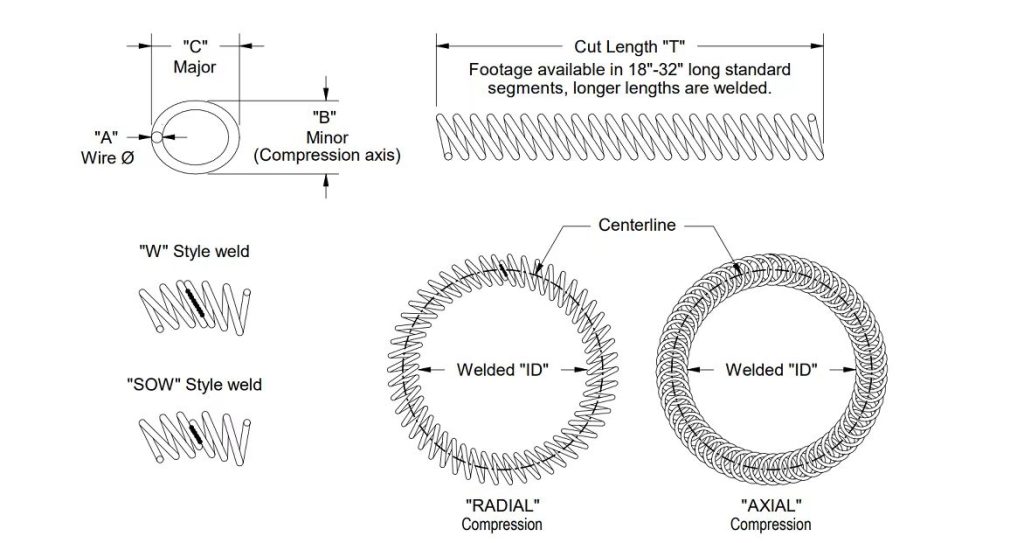

根据应用的不同,导电倾斜线圈弹簧的线圈方向可以是轴向或径向的:

轴向取向:在轴向弹簧中,线圈沿弹簧的轴线取向。这种配置通常用于面贴式安装,其中弹簧需要沿着其长度提供一致的力。

径向方向:径向弹簧有垂直于弹簧轴线的线圈。这种设计通常推荐用于壳体或活塞安装配置,其中弹簧需要在径向上施加力。

轴向和径向方向之间的选择允许在设计中优化力方向,确保有效,长期的服务。

总结

导电倾斜螺旋弹簧代表了电气和机械应用的复杂解决方案。其独特的设计提供了一个混合的性能,多功能性和定制,使其适用于广泛的应用。通过了解设计原则、材料选择和性能因素,工程师可以利用倾斜螺旋弹簧来提高设备的性能。这些弹簧有助于减小尺寸、重量和系统复杂性,同时确保可靠、长期的服务。随着技术的不断进步,倾斜螺旋弹簧仍然是追求高效和有效的工程解决方案的宝贵资产。

您可能也会喜欢

-

有效抵御电磁干扰的铝箔材料

有效抵御电磁干扰的铝箔材料EMI/EMC/RFI 屏蔽解决方案

导电铝/铜箔和导电布

一、铝箔介绍二、铝箔的特性三、铝箔的应用四、使用铝箔的注意事项五、结论 一、铝箔介绍 铝箔材料是一种由高纯度铝(通常纯度≥99%)经熔铸、热轧、冷轧及多次退火工艺制成的超薄金属箔材,厚度通常在0.006mm至0.2mm之间。其具有轻量化、高延展性、优异的光/气/水阻隔性、电磁屏蔽性及耐高低温(-70℃~300℃)特性,广泛用于食品包装(如巧克力内衬)、电子绝缘(锂电池集流体)、建筑隔热(空调风管)......