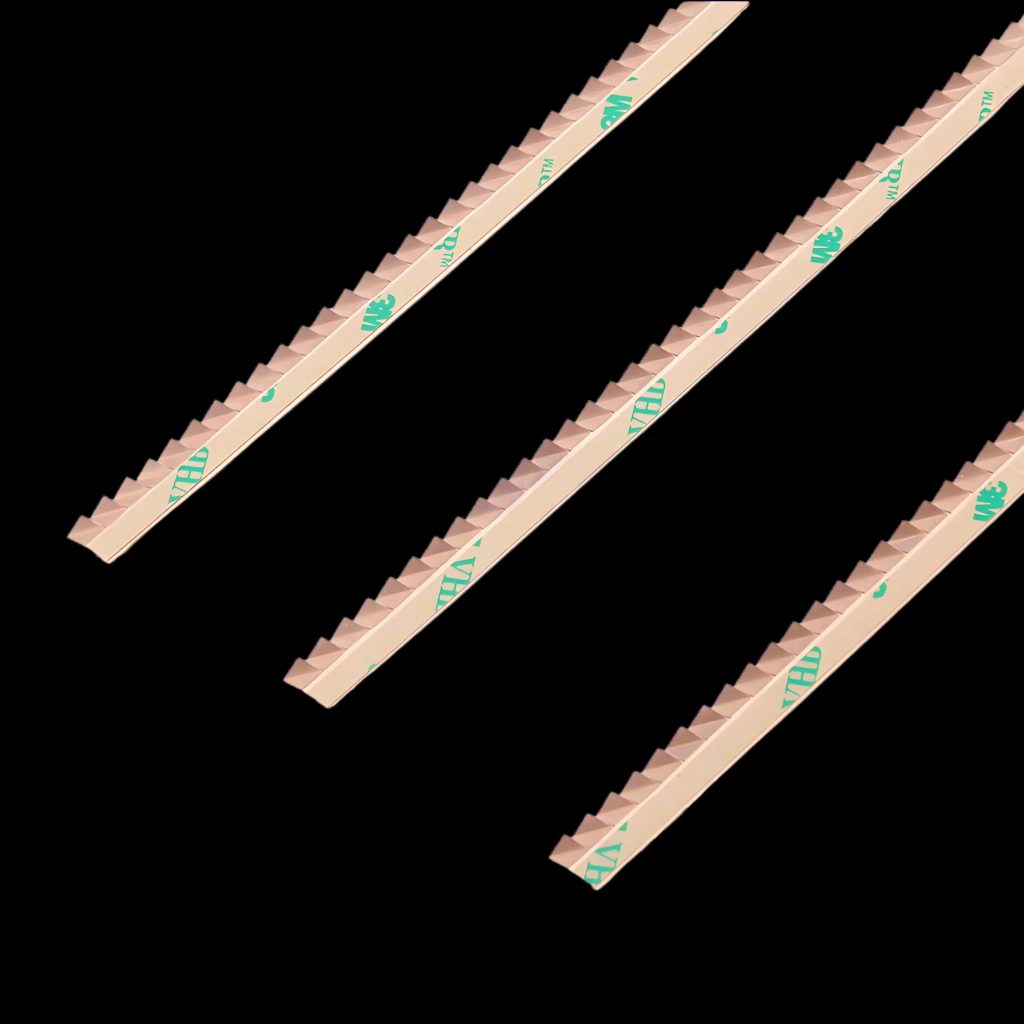

扭曲安装屏蔽指带:EMC和屏蔽解决方案中的关键组件

曲安装屏蔽指带是电磁兼容(EMC)和屏蔽解决方案中的关键组件。这些专门的条带有助于确保在各种电子和电气应用中有效的电磁干扰(EMI)屏蔽和接地。本文深入介绍了扭曲安装屏蔽指带,包括其设计、优点、应用和安装。

Table of Contents

什么是扭曲安装屏蔽指条?

扭曲安装屏蔽指带,也被称为扭曲指带或扭曲弹簧触点,是设计用于提供有效的电磁干扰屏蔽和接地的金属条。这些指带的特点是一系列金属手指以扭曲的形式排列。这种设计确保指带保持一致的接触压力,并在电子外壳和连接中提供卓越的屏蔽性能。

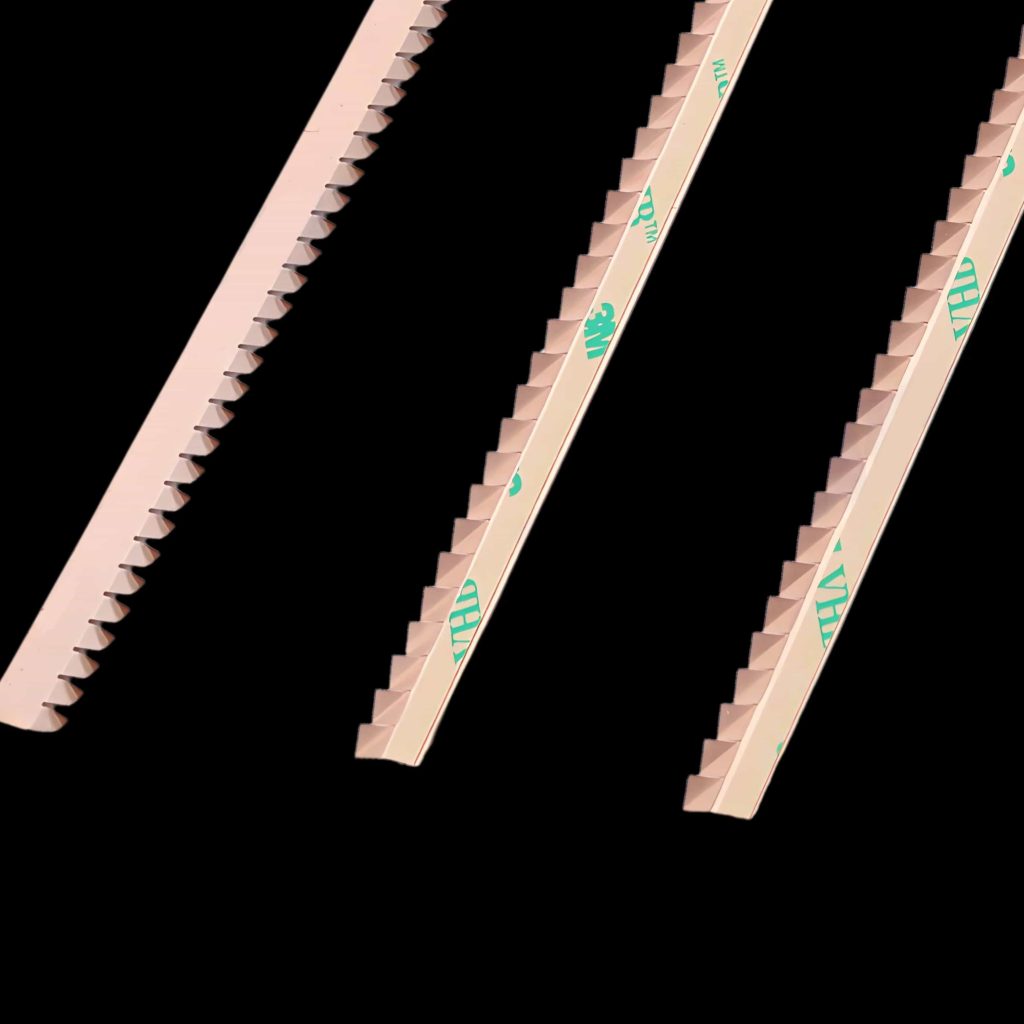

设计与特点

1.扭曲配置:这些指带的扭曲设计允许增强接触压力和灵活性。即使在机械运动或振动的环境中,它也有助于保持一致和有效的连接。

2.材料组成:扭曲安装屏蔽指带通常由高质量的导电材料制成,如铍铜,不锈钢,黄铜或磷青铜。选择这些材料是因为它们具有优异的导电性、耐腐蚀性和耐久性。

3.灵活和弹性:扭曲的配置允许手指带弯曲和适应各种表面,确保可靠的连接。这种灵活性使它们适合在动态或不规则环境中使用,传统的屏蔽方法可能会失败。

4.有效的电磁干扰屏蔽:指带创建一个连续的导电路径,有助于阻挡和转移电磁干扰。这种有效的电磁干扰屏蔽对于保持电子系统的性能和完整性至关重要。

扭曲安装屏蔽指带的好处

增强接触压力:双绞线设计提供一致的接触压力,这对于有效的电磁干扰屏蔽和接地至关重要。这有助于即使在振动或机械应力的环境中也能保持安全连接。

优越的灵活性:扭曲指带的灵活性使其符合各种表面轮廓,确保可靠的密封和一致的屏蔽性能。这种适应性使它们适用于各种应用程序。

耐用性和耐腐蚀性:由优质导电材料制成,扭曲指带具有优异的耐用性和耐腐蚀性。这确保了恶劣环境下的长期性能和可靠性。

易于安装:扭曲安装屏蔽指带设计为直接安装。它们可以很容易地安装到电子外壳或连接器上,为EMI屏蔽和接地提供了有效的解决方案。

扭曲安装屏蔽指带的应用

电子外壳:扭曲指带通常用于电子外壳,以提供有效的电磁干扰屏蔽。它们有助于防止来自外部来源的干扰,并保护敏感的电子元件免受电磁噪声的影响。

连接器屏蔽:这些指带也用于连接器屏蔽,以确保可靠的接地和屏蔽连接。它们有助于保持信号完整性并降低由于EMI而导致的信号退化的风险。

航空航天和国防:在航空航天和国防应用中,扭曲安装屏蔽指带用于屏蔽敏感设备,并确保在具有挑战性的环境中具有可靠的性能。它们的耐用性和有效的屏蔽性能使它们适合这些高风险的应用。

医疗设备:医疗保健行业在医疗设备中使用扭曲的指带来防止可能影响设备性能的电磁干扰。它们提供一致的接触压力和屏蔽的能力对于保持医疗设备的准确性和可靠性至关重要。

汽车电子:在汽车工业中,扭曲安装屏蔽指带用于屏蔽电子元件免受电磁干扰,确保汽车系统可靠运行。它们的灵活性和耐用性对于承受汽车环境的恶劣条件至关重要。

安装与维护

正确安装:为了获得最佳性能,应根据制造商的规格安装扭曲安装屏蔽指带。确保指带排列正确且安装牢固,以达到有效的屏蔽和接地效果。

定期检查:建议定期检查指带,以确保它们保持良好状态,并提供有效的电磁干扰屏蔽。检查磨损或损坏的迹象,必要时更换任何部件。

清洁和维护:在灰尘或污染物含量高的环境中,定期清洁屏蔽区域可以帮助保持最佳性能。确保指带和周围表面清洁,防止干扰,保持设备可靠运行。

总结

扭曲安装屏蔽指带是有效的电磁干扰屏蔽和接地在各种电子和电气应用的重要组成部分。它们的扭曲或螺旋设计提供了一致的接触压力和灵活性,使它们适用于各种环境。扭指带具有优异的耐用性,耐腐蚀性和易于安装,为保持电子系统的性能和完整性提供了可靠的解决方案。但如果您有其他问题,没有在这篇文章中提到,请与我们联系,我们的工程师将迅速和愉快地回答您。