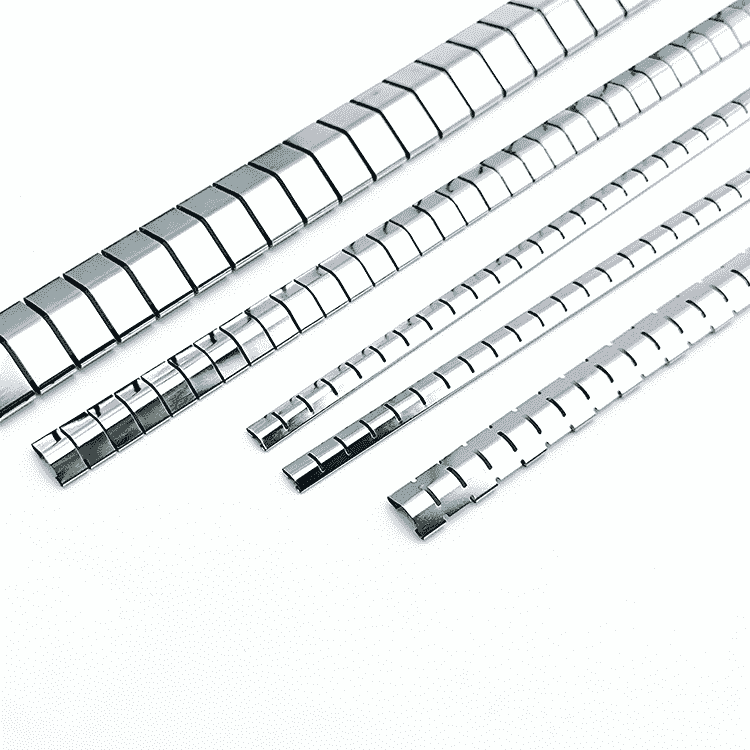

具有高电磁干扰屏蔽效果的卡扣式安装指形弹片

卡扣式安装指形弹片是一种高效的电磁干扰 (EMI) 屏蔽元件,用于各种电子外壳和组件中,以确保电磁完整性并防止射频干扰 (RFI)。随着电子系统的发展,EMI 屏蔽已成为保持敏感电子设备功能和性能的关键。卡扣式安装指形弹片具有安装简便、灵活性强、屏蔽效果好等特点,在电信、军事、航空航天、汽车和消费电子等众多行业中广受欢迎。

本文将详细探讨卡扣式安装指形弹片,重点介绍其主要特点、材料、安装方法、应用和优点。此外,我们还将探讨为什么卡扣式安装指形弹片是现代电子产品的重要组成部分,以及它们如何满足 EMI/RFI 屏蔽要求。

Table of Contents

什么是卡扣式安装指形弹片?

卡扣式安装指形弹片是一种柔性 EMI 屏蔽垫片,由铍铜、磷青铜或其他导电合金等材料制成。它们专门设计用于形成安全的电气接触,并建立有效的 EMI 屏障。卡入式指形弹片安装在电子外壳内的凹槽或轨道中,可以方便地与各种组件集成。

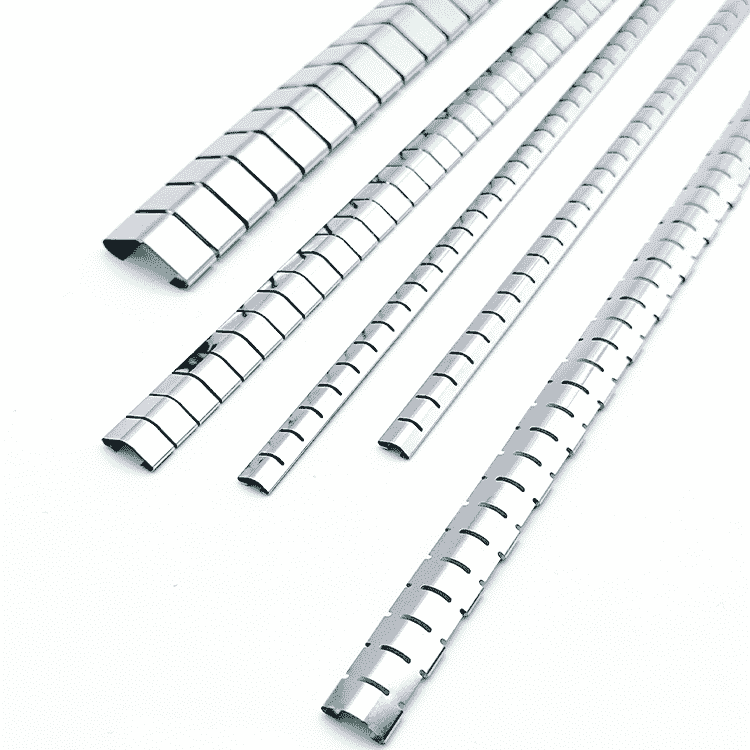

这些指形弹片采用卡扣式安装设计,简化了安装过程,只需轻轻按压即可将其牢固安装到位。在需要接触内部元件而又不影响屏蔽性能的组件中,这种特性使其独特有用。

卡扣式安装指形弹片的主要特点

1. 压缩力低

卡扣式安装指形弹片的主要优点之一是压缩力低。与其他一些需要很大力量才能安装的 EMI 屏蔽解决方案不同,这些指形弹片只需很小的压力即可压缩,因此非常适合用于滑动应用。低压缩力有助于延长垫片和相邻表面的使用寿命,减少反复组装和拆卸过程中的磨损。

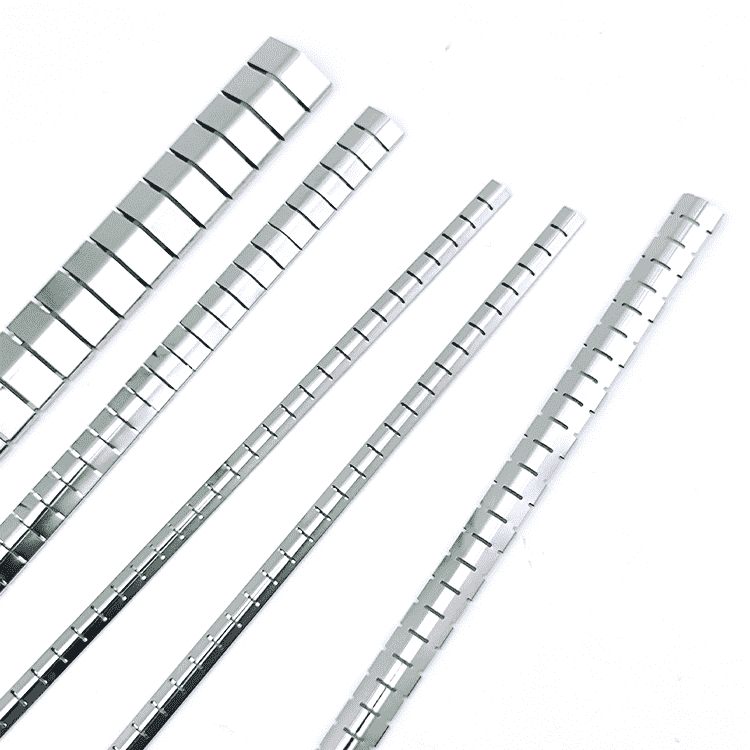

2. 对称设计

卡扣式安装指形弹片通常采用对称设计,可实现指形弹片与外壳表面的双向接触。这一特点可确保在各种表面上实现连续的屏蔽连接,从而提高整体屏蔽效果。对称设计还使指压条更容易正确安装,因为不需要特定的方向。

3. 高电磁干扰/射频干扰屏蔽效率

作为一种 EMI 屏蔽解决方案,卡入式指形弹片在阻隔电磁干扰(EMI)和射频干扰(RFI)方面非常有效。这些屏蔽组件可形成电气接地路径和物理屏障,防止电磁波泄漏到机壳内外。对于依赖信号清晰度和精确度的敏感电子设备和系统来说,这种能力尤为重要。

4. 耐用性和材料强度

卡扣式安装指形弹片通常由铍铜或其他铜合金等坚固材料制成。铍铜以其高导电性、高强度和耐腐蚀性而闻名,是苛刻环境中 EMI 屏蔽的理想材料。这种耐用性可确保卡入式指形弹片经得起反复使用,而不会失去屏蔽效果。

5. 应用广泛

卡扣式安装指形弹片用途广泛,可用于各种电子外壳和组件。其灵活性和安装简便性使其适用于各种电子设备和机柜中需要频繁开关面板、门和盖板的应用场合。

卡扣式安装指形弹片的类型

卡扣式安装指形弹片有不同的配置和材料,可满足各种应用的特定要求。常见类型包括:

1. 导电铍铜指形弹片

这是最常见的指形弹片,由铍铜制成,具有出色的导电性和弹性。铍铜指形弹片通常用于需要持续屏蔽的高性能应用中,即使在极端的环境条件下也是如此。

2. 镀锡指形弹片

有些卡扣式安装指形弹片带有镀锡层,可提高耐腐蚀性,增强弹片与外壳表面建立牢固电气接触的能力。镀锡指形弹片通常用于户外应用或存在湿气和其他腐蚀性元素的环境。

3. 带双面胶的卡扣式指形弹片

对于要求更高或更特殊的应用,卡扣式安装指形弹片可配备双面胶或安装在带背胶的黄铜轨道上。这种粘合剂便于快速安装并提供额外的固定强度。在某些情况下,指形弹片还可以刻上刻痕,以便在安装后轻松断开。

卡扣式安装指形弹片的安装方法

卡扣式安装指形弹片的主要卖点之一是安装简便。卡入式特点意味着只需将其压入外壳边缘的凹槽或轨道中,即可快速轻松地安装。

逐步安装过程:

- 准备工作: 确保安装指形弹片的凹槽或轨道干净无杂物。

- 定位: 将卡入式指形弹片的边缘固定在外壳的凹槽或边缘之一。

- 卡入:轻轻施压,将指形弹片推向第二个凹槽的方向,直到指形弹片稳固地卡入到位。

- 安全接触: 卡入到位后,指压条沿表面建立连续接触,提供有效的 EMI 屏蔽。

卡扣式安装指形弹片的常见应用

卡扣式安装指形弹片具有出色的 EMI/RFI 屏蔽能力,而且易于安装,因此应用广泛。在电子元件和组件需要经常接触或维护而又不影响 EMI 屏蔽的环境中,它们尤其有用。

1. 前面板把手

卡入式指形弹片通常用于前面板手柄,以确保 EMI 保护,同时又能方便地接触到外壳的内部组件。

2. 屏蔽外壳和门

在屏蔽外壳中,卡入式指形弹片可在门或接入点周围提供连续的电磁干扰屏障。它们可防止电磁干扰在门关闭时进入或离开外壳,因此对于必须满足严格的 EMC(电磁兼容性)标准的设备来说至关重要。

3. 滑动托盘和插入式装置

对于带有滑动托盘或插入式装置的电子柜或设备,卡扣式安装指形弹片可确保即使在移动过程中也能保持稳定的电磁干扰屏蔽。因此,对于需要频繁插拔元件的系统来说,它们是一种可靠的解决方案。

4. 机架和通信柜

安装在机架或通信机柜中的电信系统、服务器和其他数据通信设备可受益于卡入式指形弹片提供的电磁干扰屏蔽。这些指形条能保护敏感的电子元件免受外部干扰,确保数据完整性并最大限度地减少信号损失。

卡扣式安装指形弹片的材料选择

用于制造卡扣式安装指形弹片的材料在决定其有效性、耐用性和对特定环境的适用性方面起着重要作用。以下是最常用的材料:

1. 铍铜

铍铜具有出色的导电性、高强度和耐腐蚀性,是一种首选材料。它非常适合高频 EMI 屏蔽应用,并能承受包括极端温度在内的恶劣工作条件。

2. 磷青铜

磷青铜是另一种用于卡扣式安装指形弹片的材料,以良好的导电性和耐磨性著称。它常用于对机械耐久性和 EMI 屏蔽性能要求较高的应用场合。

3. 不锈钢

在耐腐蚀和耐用性要求极高的环境中,可以使用不锈钢卡入式指形弹片。不锈钢的导电性比铜合金差,但具有优异的抗氧化性,因此非常适合户外或海洋应用。

4. 镀锡合金

在需要耐腐蚀性和改善电气接触的情况下,卡扣式安装指形弹片可以镀锡。这种额外的保护层可确保在可能存在湿气或腐蚀性化学品的环境中保持长期性能。

使用卡扣式安装指形弹片的好处

卡扣式安装指形弹片具有众多优点,是各种电子和工业应用中必不可少的部件。

1. 易于安装

卡入式设计简化了安装,无需复杂的工具或安装机制。这一特点对于需要经常接触封闭元件的应用特别有用,因为指形弹片可以很容易地重新安装,而不会失去其功效。

2. 压缩力小

卡扣式安装指形弹片只需很小的压紧力,从而减少了对密封垫和外壳的磨损。这可确保更长的使用寿命,使其适用于需要反复运动或装配的应用场合。

3.有效的 EMI/RFI 屏蔽

卡扣式安装指形弹片可在很宽的频率范围内提供强大的 EMI/RFI 屏蔽。它们能够建立连续的电气接地路径和物理屏障,确保电子设备免受不必要的干扰。

4. 应用广泛

从汽车电子产品到通信系统,卡入式指形弹片可用于各行各业。它们的多功能性使其可以集成到多种配置中,成为满足现代屏蔽要求的灵活解决方案。

5. 耐用性

卡入式指形弹片可抵御恶劣环境,即使在高温、潮湿或腐蚀性环境等具有挑战性的条件下,也能确保其屏蔽性能保持不变。

结论

卡扣式安装指形弹片是许多行业 EMI 屏蔽解决方案中的重要组件。它们易于安装、压缩力小、屏蔽效果好,是处理敏感电子系统的工程师和制造商的首选。卡入式指形弹片采用铍铜、磷青铜和不锈钢等耐用材料,即使在最严苛的环境中也能提供持久的保护,并保持设备的电磁完整性。

随着 EMI/RFI 屏蔽在防止干扰和确保电子设备顺利运行方面变得越来越重要,它们在汽车、航空航天、国防、电信和消费类电子产品中的作用也在不断增强。卡扣式安装指形弹片应用广泛,性能可靠,是现代 EMI 屏蔽技术的基石。