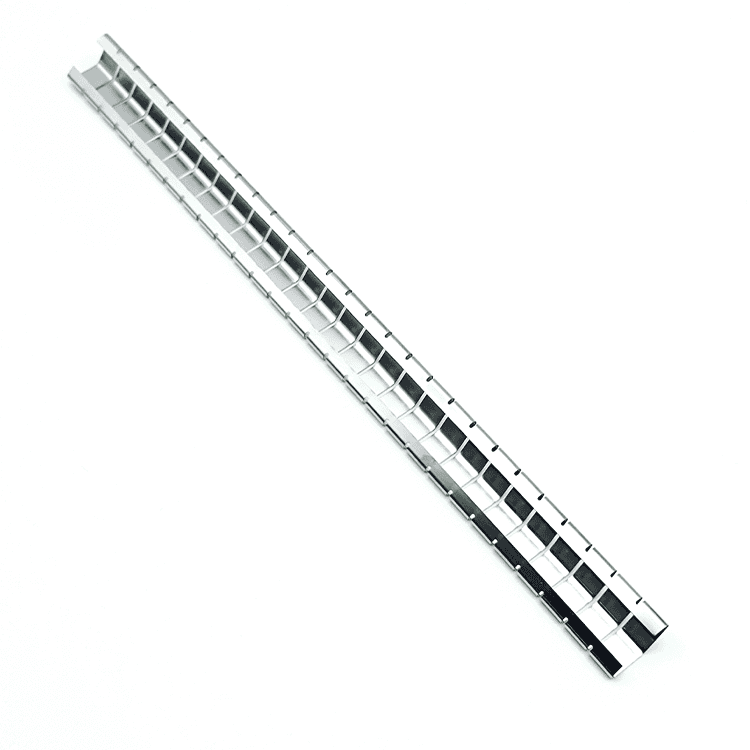

高屏蔽效能EMI屏蔽指形弹片

Table of Contents

在当今日益复杂的电子环境中,电磁干扰(EMI)屏蔽已成为设备制造商和设计人员关注的关键问题。解决电磁干扰问题的一个有效解决方案是使用高屏蔽效能的EMI屏蔽指形弹片/指形簧片。这些专用组件在保护电子设备免受不必要的电磁辐射和保持电磁兼容性(EMC)方面发挥着至关重要的作用。

电磁干扰屏蔽是什么?

电磁干扰(EMI)是指由外部源的电磁辐射引起的电子电路和系统的中断。这种干扰可以表现为噪声、信号退化或完全的系统故障。电磁干扰可以由各种来源产生,包括电气设备,通信系统,甚至自然现象。

为了对抗电磁干扰,屏蔽技术被用来阻挡或减弱电磁波。电磁干扰屏蔽包括创建一个屏障,防止干扰穿透电子设备的敏感区域。有效的电磁干扰屏蔽确保设备可靠运行,保持信号完整性,并符合监管标准。

EMI屏蔽指形弹片是什么?

EMI屏蔽指形弹片是一种用于电磁干扰(EMI)屏蔽的导电弹性元件,通常由铍铜或不锈钢制成。其多指状结构在受压时与金属外壳紧密接触,形成连续导电通路,有效反射/吸收电磁波,同时提供接地和密封功能。特点是高弹性、耐腐蚀,广泛应用于电子设备的接口、盖板等需要频繁开闭的部位。

在各种EMI屏蔽解决方案中,指形弹片因其高效而特别引人注目。这些弹片衬垫的设计是为密封电子外壳的缝隙提供一个导电路径,以阻止电磁干扰。在许多电子可靠性至关重要的行业中,它们是必不可少的组件。

EMI屏蔽指形弹片的优点

指形弹片衬垫提供了几个好处,使其成为EMI屏蔽应用的热门选择:

1.高屏蔽效能:指形弹片的主要优点是它们提供高屏蔽效能的能力。导电手指为EMI创造了一个低阻抗路径,有效地衰减了广泛频率范围内的干扰。

2.弹性和压缩:指形弹片是高度灵活的,可以符合不规则的表面。这种灵活性确保了紧密的密封和一致的接触压力,从而增强了垫片的屏蔽性能。

3.耐用性:由于坚固的材料,指形弹片是耐用的,抗磨损和撕裂。随着时间的推移,即使反复按压,它们也能保持其有效性。

4.低接触电阻:指形弹片的设计确保了低接触电阻,这对于保持高屏蔽性能和确保可靠的电气连接至关重要。

5.易于安装:指形弹片相对容易安装。它们可以使用粘合剂或机械紧固件集成到各种外壳设计中,简化了组装过程。

EMI屏蔽指形弹片的结构与材料

电磁干扰屏蔽指形弹片通常由导电金属制成,如铍铜(BeCu),不锈钢或铝。铍铜合金由于其优异的电弹簧特性和高屏蔽效能而特别受欢迎。

铍铜指形弹片的制造过程包括:

- 冲压成形金属条

- 后热处理,提高机械强度和导电性

- 精密切割,实现严格的公差

这些衬垫有各种规格和样式,以适应不同的应用需要。

EMI屏蔽指形弹片的应用

指形弹片广泛用于EMI屏蔽必不可少的行业和应用中:

1. 电信:在电信设备中,指形弹片有助于屏蔽敏感元件免受电磁干扰,确保清晰可靠的信号传输。

2. 医疗设备:对于精度和可靠性至关重要的医疗设备,指形弹片提供有效的屏蔽,以防止可能危及患者安全的干扰。

3. 航空航天和国防:在航空航天和国防应用中,电子系统受到极端条件的影响,指形弹片提供强大的屏蔽和可靠性。

4. 消费电子产品:指形弹片也用于消费电子产品,如电脑、电视和音频设备,以防止EMI并保持最佳性能。

5. 汽车:在汽车工业中,指形弹片用于屏蔽各种电子系统免受电磁干扰,确保车辆部件的正常运行。

EMI屏蔽指形弹片的性能指标

为了评估EMI屏蔽指形弹片/指形簧片的性能,考虑了几个关键指标:

1. 屏蔽效能:这一指标表明垫片衰减电磁辐射的能力。它通常以分贝(dB)为单位测量,反映了衬垫阻挡EMI的效果。

2. 接触电阻:衬垫与配合表面接触时所遇到的电阻。更低的接触电阻意味着更好的导电性和屏蔽性能。

3. 压缩力:在表面之间压缩垫片所需的力。适当的压缩是实现紧密密封和有效屏蔽所必需的。

4. 环境阻力:衬垫承受环境因素的能力,如温度变化、湿度和机械应力。

5. 使用寿命:垫圈保持其有效性的持续时间。耐久性是需要长期可靠性的应用程序的关键因素。

挑战与考虑

虽然指形弹片提供了许多优点,但必须解决的挑战和考虑因素:

1. 成本:由于材料和制造工艺的关系,高质量的指托/指带垫圈价格昂贵。平衡成本和性能需求是必要的。

2. 安装:正确的安装对最佳屏蔽效果至关重要。不对中或不适当的压缩会降低垫片的性能。

3. 兼容性:材料的选择和设计应与具体的应用和环境条件相适应。

4. 维护:定期检查和维护是必要的,以确保垫圈继续有效地发挥作用。

电磁干扰屏蔽的未来趋势

随着技术的进步,对有效的EMI屏蔽解决方案(包括指形弹片)的需求将继续增长。电磁干扰屏蔽的未来趋势可能包括:

1. 增强材料:开发具有更高导电性和耐久性的新材料,以进一步增强屏蔽性能。

2. 集成智能技术:将传感器和智能技术集成到垫片中,实时监控和优化屏蔽性能。

3. 小型化:设计进步,以适应电子设备的小型化,同时保持高屏蔽效能。

4. 可持续解决方案:专注于环保材料和制造工艺,以减少EMI屏蔽解决方案对生态的影响。

高屏蔽效能电磁干扰屏蔽指形弹片的案例研究

为了说明指形弹片的实际应用和有效性,可以考虑几个案例研究:

1. 电信设备

一家主要的电信公司在其网络设备外壳中实施了EMI屏蔽指形弹片。衬垫成功地降低了电磁干扰,从而提高了信号清晰度和可靠性。垫圈的高屏蔽效能对于满足行业标准和确保不间断服务至关重要。

2. 医疗设备

在医院环境中,电磁干扰屏蔽指形弹片用于敏感的医疗诊断设备的外壳。垫圈提供了有效的电磁干扰屏蔽,防止可能影响诊断读数准确性的干扰。垫圈的耐用性确保了在苛刻环境下的长期可靠性。

3. 汽车电子

一家汽车制造商将指形弹片集成到他们的车辆控制系统中,以屏蔽电磁干扰。这些垫圈保持了车辆电子元件的最佳性能,有助于提高车辆的整体可靠性和安全性。

结论

电磁干扰屏蔽指形弹片在保护电子设备免受电磁干扰方面起着至关重要的作用。其独特的设计,具有弹性金属指和支撑底座,在广泛的频率范围内提供卓越的屏蔽性能。指形弹片具有灵活性,耐用性和易于安装等优点,广泛用于电信,医疗设备,航空航天,消费电子产品和汽车应用。

随着技术的不断发展,对有效的EMI屏蔽解决方案的需求将会增长。通过解决与成本、安装和兼容性相关的挑战,并跟上未来的趋势,制造商和用户可以确保EMI屏蔽指形弹片仍然是对抗电磁干扰的持续战斗中的重要组成部分。