你认识直角屏蔽指带吗?

直角屏蔽指带 是电子和电气系统中的关键部件,旨在提供有效的电磁干扰(EMI)保护并确保可靠的接地。这些组件在需要尽量减少干扰、接地和接触问题的环境中是必不可少的。直角设计允许这些指带适合狭窄的空间或周围的角落,使其多功能和适用于广泛的应用,从消费电子产品到航空航天和国防系统。

Table of Contents

直角屏蔽指条的特点

直角屏蔽指带的特点是有几个关键的特点,有助于他们的有效性和多功能性:

1.直角设计

配置:直角设计是一个独特的特点,允许指带安装在空间,传统的线性条可能不适合。这种配置在紧凑的电子组件中特别有益,其中空间非常宝贵,例如在现代消费电子产品或密集包装的工业设备中。直角弯曲有利于角落和边缘的屏蔽,这往往是电子外壳中最脆弱的点。

空间利用:直角配置最大限度地利用可用空间,允许有效地集成到设计中,直线屏蔽将是不切实际的。这使得它成为需要紧凑、高密度组件布局的应用的理想解决方案。

2.电磁干扰屏蔽能力

电磁干扰(EMI)保护:直角屏蔽指带的主要功能是保护敏感的电子元件免受电磁干扰。电磁干扰可以来自各种来源,包括其他电子设备,电力线,甚至是环境因素,如太阳辐射。通过在这些干扰源和受保护元件之间提供屏障,指带确保电子设备在不降低性能的情况下运行。

辐射吸收和反射:指带的材料和设计经过优化,可以吸收或反射入射的电磁波,从而防止电磁波到达敏感区域。这种双重能力对于保持高频信号的完整性至关重要,因为高频信号特别容易受到EMI的干扰。

3.材料组成

导电材料:直角屏蔽指带通常由高导电性金属制成,如铜、铍铜或不锈钢。选择这些材料是因为它们具有优异的导电性、耐腐蚀性和机械耐久性。在某些情况下,金属可以镀上额外的导电层,如镍、金或银,以增强其屏蔽效果和对环境因素的抵抗力。

环境恢复力:这些手指带的建造材料也是根据其承受恶劣环境条件的能力而选择的,包括极端温度、湿度和化学品暴露。这确保了即使在要求苛刻的应用中,屏蔽也能长期有效。

4.指带构造

灵活的接触手指:直角屏蔽指带的一个关键特点是多个灵活的接触手指的存在。这些手指的设计是为了与它们屏蔽的表面保持一致的电接触,确保安全可靠的连接。手指的灵活性使它们能够适应表面排列的细微变化,或者在振动或热膨胀的情况下保持接触。

连续接触:指带的结构确保接触手指沿着整个长度提供连续的屏蔽。这对于需要全面电磁干扰保护的应用至关重要,因为即使是很小的屏蔽间隙也会导致显著的性能问题。

直角屏蔽指条的应用

直角屏蔽指带广泛应用于各个行业。它们提供可靠的电磁干扰屏蔽和接地的能力使它们在许多关键系统中必不可少。

1.电子及电气设备

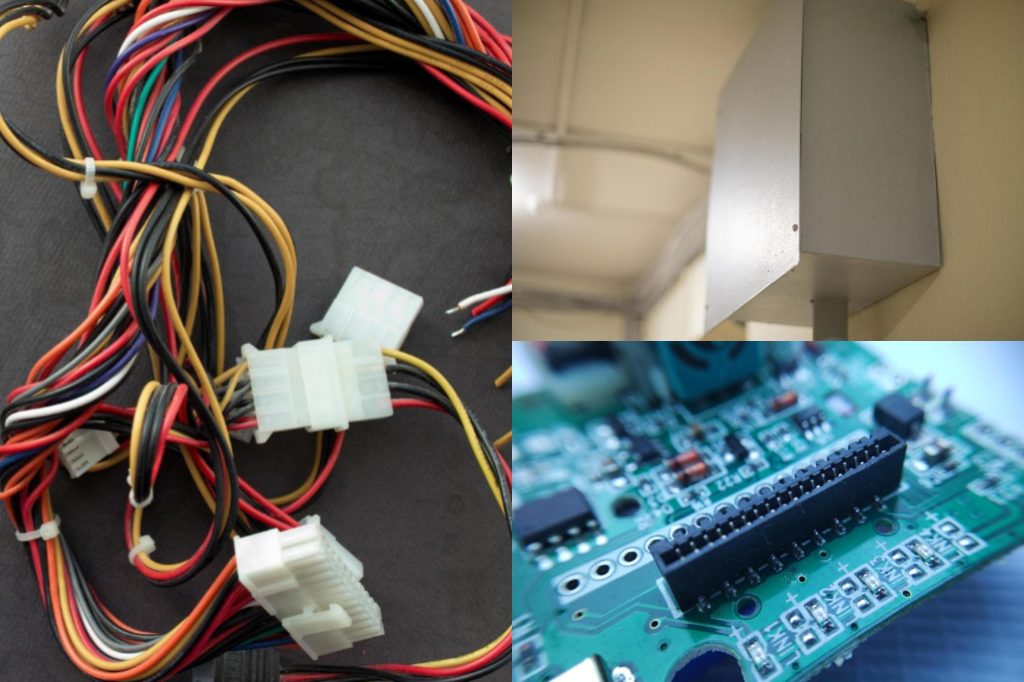

PCB连接器:在印刷电路板(PCB)中,直角屏蔽指带用于屏蔽连接器,防止电磁干扰影响信号完整性。这些指带提供的可靠接地对于保持电子电路的稳定性,确保数据传输保持准确和电子元件按预期工作至关重要。

电缆组件:直角屏蔽指带通常集成到电缆组件中,以保护内部电线免受外部干扰。通过提供对EMI的屏障,这些指带有助于确保通过电缆传输的信号保持清晰和不失真,这对于高速数据通信和电力输送至关重要。

外壳屏蔽:在电子外壳中,直角屏蔽指带用于密封缝隙,并沿着接缝和角落提供连续的电磁干扰保护。这在存在多个面板或接入点的设计中尤其重要,因为这些区域特别容易受到干扰。

2.通信系统

数据接口:在数据通信系统中,维护数据完整性是至关重要的。直角屏蔽指带用于数据接口,以防止外部噪声引起的信号退化。这在高频应用中尤其重要,因为即使很小的干扰也会导致严重的数据丢失或损坏。

网络设备:在路由器、交换机、调制解调器等网络设备中,直角屏蔽指带可提供必要的电磁干扰屏蔽,确保设备可靠运行。这些设备通常在高水平电磁活动的环境中运行,因此有效的屏蔽对于保持网络性能和可靠性至关重要。

3.消费电子产品

计算机和移动设备:在消费电子领域,直角屏蔽指带通常用于计算机、智能手机和平板电脑等设备。这些设备包含许多敏感元件,必须保护它们免受电磁干扰,以确保平稳运行。直角指带的紧凑设计使其非常适合在这些空间受限的应用中使用。

可穿戴技术:随着可穿戴设备变得越来越普遍,对紧凑外形的有效电磁干扰屏蔽的需求也在增加。直角屏蔽指带非常适合用于智能手表、健身追踪器和其他可穿戴技术,它们有助于保护设备的敏感组件免受干扰,而不会增加体积。

4.汽车应用程序

汽车电子产品:现代汽车严重依赖电子系统,从发动机管理到信息娱乐。直角屏蔽指带用于保护关键组件和布线免受电磁干扰,确保这些系统可靠运行。这在电动和混合动力汽车中尤为重要,因为高压系统会产生显著的电磁噪声。

自动驾驶系统:在自动驾驶汽车中,传感器数据和通信系统的完整性对于安全运行至关重要。直角屏蔽指带有助于保护这些系统免受干扰,确保车辆的控制系统接收到准确可靠的信息。

5.航空航天与国防

敏感设备:航空航天和国防应用通常涉及高水平电磁干扰的环境。直角屏蔽指带用于保护敏感电子设备免受环境和操作EMI的影响,确保这些系统在具有挑战性的条件下保持功能。

军事通信系统:在军事应用中,安全可靠的通信至关重要。直角屏蔽指带用于通信设备,防止信号截获和退化,有助于保持军事行动的完整性。

直角屏蔽指带的好处

直角屏蔽指带提供了许多好处,使它们在广泛的应用中不可或缺:

1.增强信号完整性

提高性能:通过屏蔽连接和组件免受电磁干扰,直角屏蔽指带有助于保持信号完整性。这在高频应用中尤为重要,因为即使很小的干扰也会导致显著的性能问题。

数据保护:在数据通信系统中,直角屏蔽指带通过确保传输信号不受干扰来防止数据损坏或丢失。这对于保持数据传输的准确性和可靠性至关重要。

2.减少干扰

最小化噪音:直角屏蔽指带提供有效的电磁干扰屏蔽,减少外部电磁噪音,否则会干扰电子设备的操作。这种降噪在高水平电磁活动的环境中尤其重要,例如工业或军事环境。

提高可靠性:通过防止干扰,直角屏蔽指带提高了电子系统的整体可靠性。在医疗或航空航天设备等系统故障可能造成严重后果的应用中,这一点至关重要。

3.空间效率

紧凑的设计:这些指带的直角设计允许在狭窄或受限的区域有效地利用空间。这使得它们非常适合用于空间有限且仍然需要有效屏蔽的紧凑型电子组件。

多功能性:直角屏蔽指带的紧凑设计使其可用于各种应用,从消费电子产品到工业设备。这种多功能性使它们成为许多不同类型的电子系统中有价值的组件。

4.耐久性和可靠性

长期性能:直角屏蔽指带由耐用材料制成,设计用于承受环境应力,并随着时间的推移保持有效的屏蔽。这种耐用性对于设备必须长时间保持运行的应用至关重要,即使在具有挑战性的条件下也是如此。

对环境因素的抵抗性:这些指带所用的材料是根据其对环境因素(如温度波动、湿度和化学品暴露)的抵抗性而选择的。这确保了即使在恶劣的环境中屏蔽仍然有效。

5.简易整合

适应性强的设计:直角屏蔽指带的多功能设计使它们能够轻松地集成到各种电子和电气系统中。这种适应性使它们成为工程师和设计师在各种项目上工作的方便解决方案。

可定制选项:直角屏蔽指带可以定制,以满足不同应用的特定需求。这种定制可以包括调整手指带的尺寸、材料和配置,以确保在任何给定的应用程序中实现最佳性能。

结论

综上所述,直角屏蔽指带是确保电子和电气系统保护和可靠性的重要组件,特别是在空间有限且屏蔽对性能至关重要的情况下。它的设计和材料特性使其成为减少干扰和维护各种应用系统完整性的宝贵资产。