导电布胶带

Table of Contents

导电布胶带是什么?

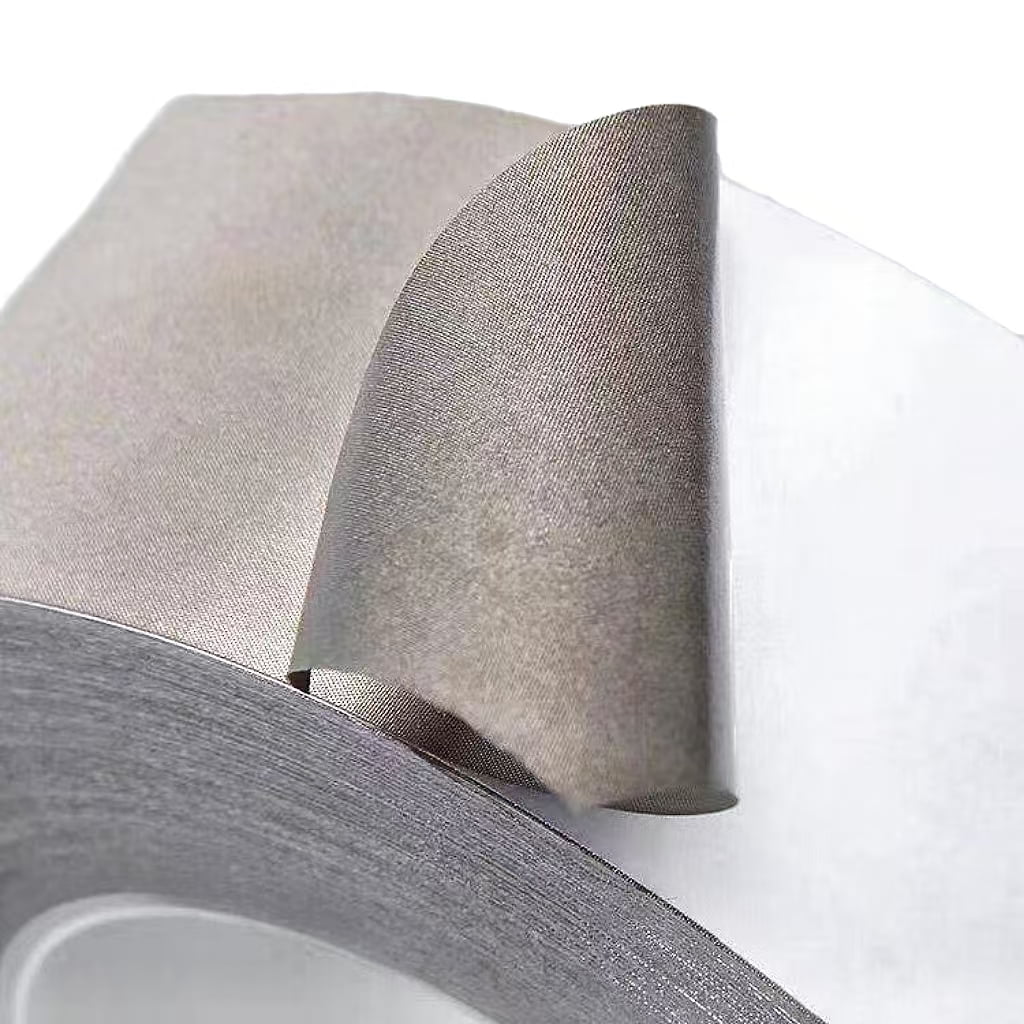

导电布胶带是一种结合导电纤维布基材和导电胶粘剂的功能性胶带,兼具电磁屏蔽(EMI)、接地导通、柔韧性及粘接特性。其核心功能是通过低电阻通路转移或消散电磁干扰,同时提供物理保护。导电布胶带的发展源于对通用、耐用和导电材料的需求。最初,导电布胶带主要用于航空航天和国防工业,但随着电子和电信成为日常生活中不可或缺的一部分,它们的用途已经扩大。

组成和类型

1.布底

导电布胶带的背衬由各种布材料制成,包括:

- 机织织物:机织织物通常由聚酯或尼龙等纤维制成,具有高拉伸强度和耐用性。

- 无纺布:无纺布是由纤维通过化学、机械或热方法粘合在一起制成的。与编织类型相比,非织造背衬通常更灵活和舒适。

2.导电层

胶带的导电层赋予了它电性能。它可以由以下材料制成:

- 金属颗粒:通常是铝、铜或银颗粒,嵌在树脂基体中。这些粒子为电流创造通路。

- 导电聚合物:碳或聚苯胺等材料用于提供导电性。它们通常用作涂层或集成到粘合剂层中。

3.粘接层

用于导电布胶带的粘合剂必须既牢固又具有导电性。胶粘剂的种类包括:

- 丙烯酸胶粘剂:以其牢固的粘合和耐环境因素而闻名。

- 橡胶基粘合剂:提供良好的初始粘性和附着力,但在某些条件下可能降解得更快。

4.导电布胶带的种类

导电布胶带根据其性能和用途可分为:

- 电气接地带:用于电气元件接地,防止静电积聚。

- 屏蔽磁带:提供电磁干扰(EMI)和射频干扰(RFI)屏蔽。

- 耐热胶带:设计用于承受高温,同时保持其导电性能。

导电布胶带的应用

1.电子与电气领域

- 屏蔽与隔离:导电布胶带在诸如电脑、手机、电线和电缆等电子电气产品的制造中被广泛应用。它在高频传输过程中对于屏蔽或隔离电磁干扰(EMI)和射频干扰(RFI)起着至关重要的作用。

- 连接与接地:它有助于电子设备的连接,并确保可靠的接地。例如,在手机内部,导电布带将电路板上的不同部件连接起来,确保电流稳定传输和信号正常通信。

- 电磁屏蔽:在电脑显示器、笔记本电脑及类似设备中,它被用于屏蔽电磁干扰,从而提高设备的稳定性和抗干扰能力。

- 维护:在电子产品维护中,导电织物胶带充当临时导电材料,有助于检测和修复故障部件。

2.航空航天领域

- 电气管理:在飞机和航空设备中,导电布带用于管理电气连接,屏蔽电子元件免受电磁干扰,并确保飞行系统的可靠运行。

- 屏蔽与连接:对于飞机的关键部件,如导航系统、通信设备和飞行控制系统,导电织物胶带可提供电磁屏蔽和导电连接,有助于整体飞行安全。

3.汽车领域

- 电磁屏蔽:在汽车电子系统中,包括发动机控制系统、车载娱乐系统和传感器,导电布胶带可屏蔽电磁干扰,以确保信号传输准确和系统功能正常。

- 线束保护:用于线束包装,以固定和保护线束,同时防止线束之间的电磁干扰。

4.通信领域

- 信号完整性:导电布带在屏蔽通信设备和电缆免受电磁干扰方面至关重要。它能保持信号的完整性,确保数据传输的准确性和稳定性,在基站设备和通信电缆中尤为常见。

5.工业领域

- 接地与屏蔽:在工业设备和自动化控制系统中,导电布带用于接地和屏蔽,以防止电磁干扰并保持设备性能。它被应用于大型机床、自动化生产线和电力设备,以屏蔽外部电磁干扰。

- 静电控制:在化工和石油等行业,它有助于防止静电积聚和火花产生,从而降低危险环境中发生爆炸的风险。

6.医疗领域

- 电极连接与屏蔽:导电胶带在心电图机和脑电图机等医疗设备中用于电极连接。它还在各种医疗设备中提供电磁屏蔽。

7.消费电子领域

- 内部连接与屏蔽:在智能手机、平板电脑和数码相机等消费电子产品中,导电布带增强了内部连接,并提供屏蔽,从而提升产品性能和可靠性。例如,它被用于天线连接和相机模块。

- 周边配件:适用于耳机线和充电线等周边配件的屏蔽和抗干扰。

8.防护服生产

- 防护服:导电布胶带可用于制造专业屏蔽工作服,适用于高电磁辐射的工作环境,保护工作人员免受潜在危害。

9.其他领域

- 科学研究:在研究实验中,导电布胶带能够搭建临时导电电路。

- DIY 和手工艺:它还用于创意 DIY 项目和手工艺品制作,兼具导电和装饰的双重优势。

导电布胶带的优点

1.电导率

导电布胶带的主要优点在于其导电性能。这使其成为需要接地、屏蔽和静电控制的应用的理想选择。

2.耐久性

导电布胶带专为恶劣环境设计,包括高温、化学物质和机械应力。其布质背衬增加了强度和耐用性。

3.灵活性与顺应性

这种布质背衬使胶带能够贴合不规则的表面和轮廓,使其适用于复杂装配和需要柔韧性的应用场合。

4.易用性

导电布胶带易于贴附,其自带的粘性背衬能牢固地粘贴在各种表面上。这种易于贴附的特点减少了人工和安装时间。

5.多功能性

由于其种类繁多、性能各异,导电布带用途广泛,可应用于不同行业的众多领域。

导电布胶带的局限性

1.成本

导电布胶带由于包含导电材料以及采用专门的制造工艺,其价格可能比非导电胶带更高。

2.粘合性能

胶粘剂的性能会因环境条件而异。在高温或强腐蚀性环境中,胶粘剂可能会更快降解。

3.电阻

虽然导电布胶带具有导电性,但其电阻会因所用导电层的厚度和类型而有所不同。对于需要极低电阻的应用,可能需要采用其他解决方案。

4.表面处理

为达到最佳性能,在贴上导电布带之前,表面应清洁且无污染物。表面处理不当会影响粘附性和导电性。

安装与维护

1.准备工作

确保表面干净、干燥,且无灰尘或油污。这有助于实现最佳的附着力和导电性。

2.应用

将胶带紧紧按压在表面上。为获得最佳效果,请使用滚轮或类似工具确保良好接触和粘合。

3.检验

应定期检查胶带是否有磨损或损坏的迹象。在胶带完整性对性能至关重要的关键应用中,这一点尤为重要。

4.更换

根据需要更换胶带以保持其功能。在磨损严重或极端条件下,可能需要更频繁地更换。

未来趋势与创新

1.高级导电材料

对于性能更优的先进导电材料的研究仍在进行中,比如更高的导电性或更强的环境耐受性。纳米技术和材料科学方面的创新可能会带来新型导电布带,其性能得到提升。

2.智能导电胶带

将智能技术融入导电布带,能够实现诸如自我修复、实时监测和自适应导电性等功能。这些创新能够拓展导电布带的应用范围和功能。

3.可持续解决方案

随着环境问题的日益严重,人们对开发可持续和生态友好的导电材料越来越感兴趣。未来的导电布胶带可能采用可回收或可生物降解的材料。

结论

导电布胶带在许多当代应用中成为关键元素,提供不可或缺的导电性,卓越的耐用性和出色的灵活性。它的应用横跨广泛的行业,从电子和电信到汽车和航空航天领域。了解它的组成、应用、优点和局限性,使用户能够做出明智的决策,并在不同的设置中优化其性能。

随着技术的不断发展,材料的进步和创新应用将不断提高导电布胶带的能力,保证其在满足各种行业要求方面的相关性和有效性。如果您需要导电布胶带或其他导电胶带,如铜箔或铝箔胶带,请立即与我们联系。