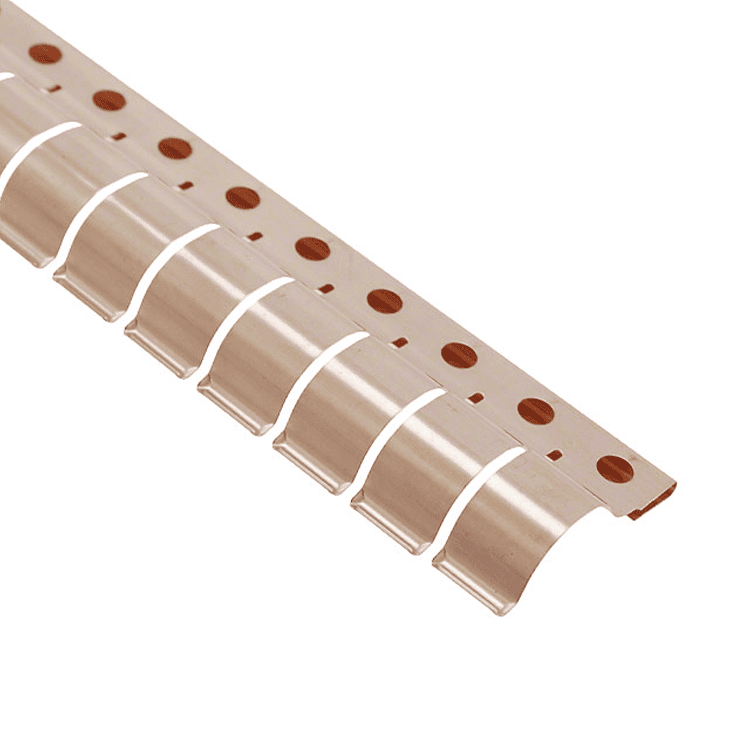

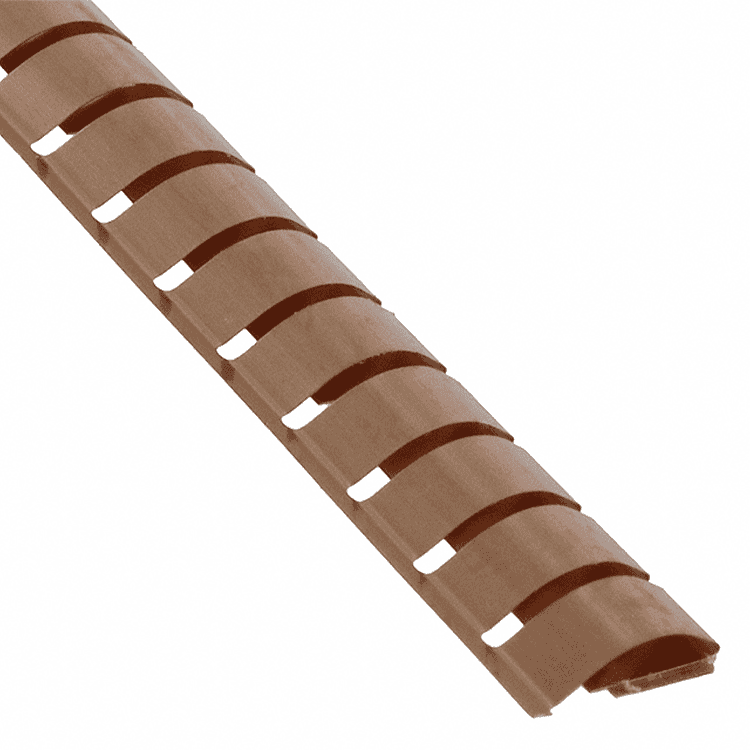

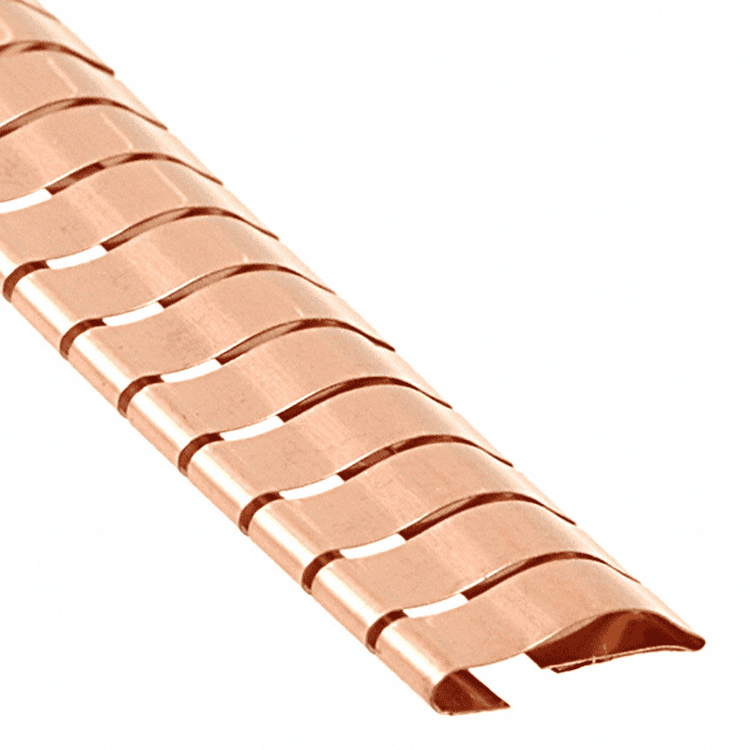

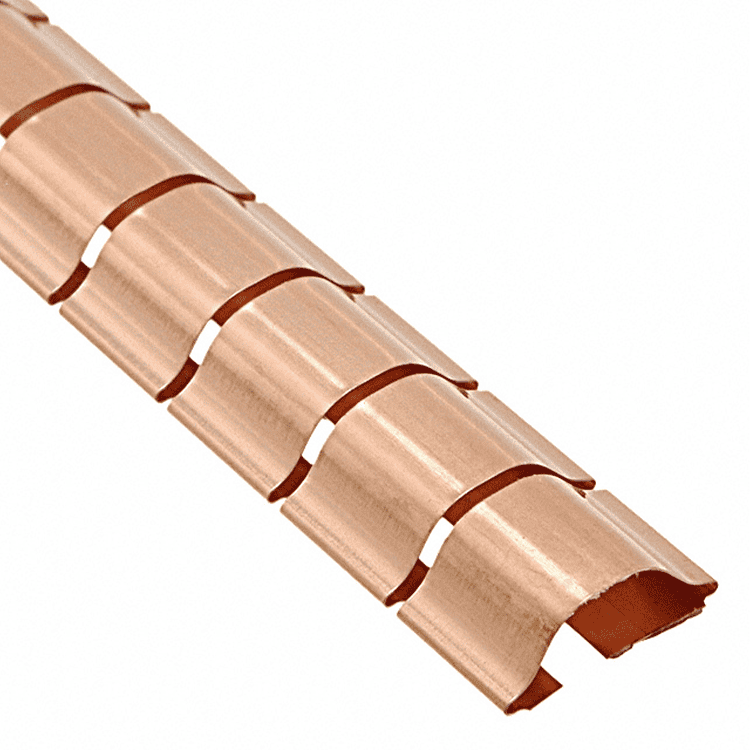

铍铜(BeCu)对指束(指带)的7个好处

铍铜(BeCu)是一种高性能合金,以其优异的机械和物理性能而闻名,使其成为各种工业应用的首选材料。BeCu的关键用途之一是制造指带,指带是一系列电子和机械系统中的重要部件。本文探讨了BeCu用于指束(指带)的好处,强调了其优越的性能及其对性能和可靠性的影响。

Table of 7 Benefits

1.优异的机械性能

a.高强度、高硬度

铍铜以其非凡的强度和硬度而闻名。经过热处理后,BeCu具有很高的抗拉强度,使其成为需要在机械应力下保持结构完整性的指托(指带)的理想材料。这种强度确保指托可以承受反复循环的压缩和膨胀而不会变形或失效。

b.优异的弹性

指托(指条)通常用作弹簧触点或密封元件,需要具有优异弹性的材料以确保正常工作。BeCu的高弹性模量使其在变形后能够恢复原始形状,确保在电气连接器和密封件等应用中具有可靠和一致的性能。

c.抗疲劳性能优越

反复的机械应力会导致材料的疲劳失效。BeCu的高抗疲劳性意味着由这种合金制成的指托可以承受无数次的加载和卸载循环,而不会出现疲劳相关问题。在要求苛刻的应用中,这种特性提高了组件的使用寿命和可靠性。

2.优异的导电性

a.高导电性

铍铜结合了高强度和良好的导电性,这是一种罕见的组合,使其在电子应用中的指托特别有价值。该合金的导电性足以有效传输电流,这对于电触点、开关和连接器等元件至关重要,因为高效的电气性能是必不可少的。

b.减少信号损耗

在电子系统中,信号完整性是至关重要的。BeCu的导电特性有助于最大限度地减少信号损失,确保高质量的电气性能。这在精密电子产品中尤其重要,因为即使是轻微的信号退化也会影响整体功能。

3.优异的耐腐蚀性和耐磨性

a.耐腐蚀性

与其他铜合金相比,BeCu具有优异的耐腐蚀性。这对于在暴露于潮湿,化学物质或其他腐蚀性元素的环境中使用的指托至关重要。耐腐蚀性确保指托随着时间的推移保持其性能和外观,减少了频繁更换和维护的需要。

b.耐磨性

指托在操作过程中经常经历摩擦和磨损。BeCu的高硬度和耐磨性使其在与其他表面频繁接触的应用中经久耐用。这种耐磨性有助于防止指托的退化,保持其功能完整性并延长其使用寿命。

4.高导热性

a.有效散热

BeCu具有良好的导热性,有利于电子和机械系统的有效散热。对于指托来说,这种特性有助于管理操作过程中产生的热量,防止过热并确保稳定的性能。在高电流应用中,有效的散热尤为重要,因为过高的热量会导致性能问题或组件故障。

b.热稳定性

除了良好的导热性外,BeCu还能在很宽的温度范围内保持其性能。这种热稳定性确保指托可以在不同的环境条件下可靠地工作,而不会显著改变其机械或电气特性。

5.制造的精准度和多功能性

a.易于制造

BeCu可以精确地加工和成形,允许生产具有严格公差和复杂几何形状的指托。这种精度对于需要精确尺寸和形状以确保适当配合和功能的应用至关重要。在不影响其性能的情况下将BeCu制造成复杂设计的能力增加了其作为指托材料的多功能性。

b.表面光洁度和外观

铍铜可以实现光滑的表面光洁度,这对于需要美学质量或特定表面性能的应用非常重要。这种抛光可以通过减少摩擦和改善电子元件的接触质量来提高指托的整体性能。

6.成本效益

a.长期成本节约

虽然BeCu可能比其他一些材料更昂贵,但其优越的性能有助于长期节省成本。BeCu指托的高强度,耐磨性和寿命减少了更换和维护的频率。这可以降低用户的总体成本,特别是在高需求或关键应用程序中。

b.减少停机时间

BeCu指托的可靠性最大限度地降低了组件故障的风险,这可能导致昂贵的停机时间和维修。在工业和电子系统中,减少停机时间对于保持生产力和运行效率至关重要。BeCu的耐用性和性能有助于降低这些风险。

7.环境及安全考虑

a.可降解

铍虽然是BeCu的关键成分,但它的使用是有控制的,以确保合金在最终形式下仍然是安全的。现代制造工艺和安全法规最大限度地减少了与铍接触相关的风险,使BeCu成为环境和健康考虑很重要的应用中更安全的选择。

b.再循环能力

BeCu是可回收的,有助于环境的可持续性。可回收性减少了合金对环境的影响,支持循环经济,与其他材料相比,BeCu是一种更环保的选择。

总结

铍铜为指托(指带)提供了一系列好处,包括卓越的机械性能,高导电性和导热性,卓越的耐腐蚀性和耐磨性,以及制造精度。这些优点使BeCu成为需要可靠、高性能组件的应用程序的绝佳选择。虽然BeCu的初始成本可能更高,但其长期耐用性、减少维护需求和性能优势提供了显著的价值。此外,对环境影响和安全性的考虑进一步增强了BeCu作为高级指托(指带)应用材料的吸引力。瀚达科技公司有各种各样的BeCu指套(指带),如贴装式屏蔽指带,扭装式屏蔽指带等,如果您需要,请立即与我们联系。